Permanent ballast retainers

Increased travel speeds and axle loads are placing ever greater requirements on track systems. A permanent ballast retainer increases the stability of the railway line with durable, long-lasting effect.

Application case

Stabilisation of transition areas

Ballast track and slab track not only exhibit different compressive strengths and compactions but also different elasticity values. To maintain safety and passenger comfort as well as preserve the rolling stock, the entire surface of expansion joints can be bonded. The bonding is V-shaped to ensure a smooth rolling transition.

Full-surface ballast bonding (below the rubber pads) can also play a valuable role in considerably extending the service life of level crossings (when a track section crosses a road without a change in height).

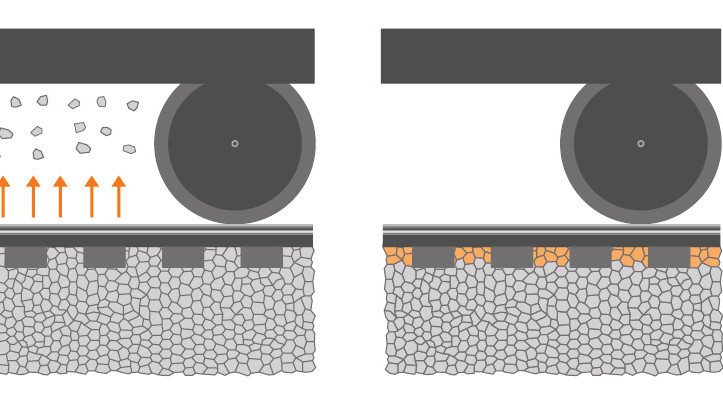

Prevention of ballast flight and ballast movement

Surfaces of high-speed lines

The suction resulting from high-speed trains causes flying ballast. This can result in damage to the tracks, the trains and facilities in areas adjacent to the tracks. Full-surface ballast bed bonding prevents track ballast from being whirled up and tossed about.

Seal ballast surfaces

To reduce the cost of cleaning the track ballast in train stop areas and at railway stations, we recommend using full-surface bonding – if necessary in combination with a fine granulate in the upper ballast area.

If the track ballast is not bonded, ballast stones are sucked up with the dirt during mechanical cleaning using suction equipment, damaging the screens and filters. The use of high-pressure cleaners can also cause the ballast to shift. Bonding the ballast near to the surface enables optimum processing by the facility management team.

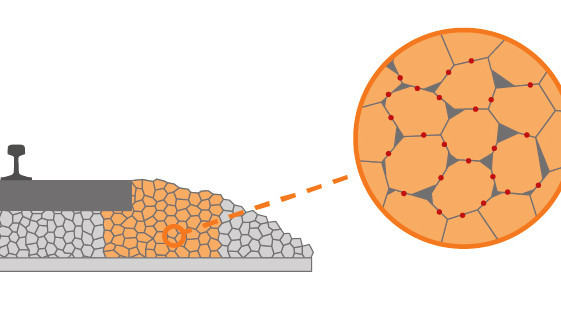

Water permeability is still un changed

As the ballast is spot-bonded, the ballast track’s water permeability is entirely maintained, eliminating the danger of shifting or washouts even during heavy rainfall or cleaning work with high-pressure cleaners.

Increasing resistance to lateral displacement

Insufficient ballast at the sleeper head can lead to track distortion, particularly where radii are tight and before signals, switches and platforms. Ballast bonding prevents ballast movement and, in the form of deep bonding to the lower edge of the ballast bed, greatly enhances resistance to lateral displacement. Ballast bonding is environmentally friendly and improves the track’s stability. Long-term tests by the German Railway`s (Deutsche Bundesbahn) Central Office and the Technical University of Munich confirm the extremely high load capacity of tracks stabilised by bonding. Bonding eliminates ballast movement, which loosens the ballast under the sleepers or exposes the rail head. The high long-term stability also greatly extends the tamping intervals. Bonding therefore significantly reduces maintenance costs. The bonded ballast can be tamped, reused and even re-bonded.